| Plasma Cutting Machine |

Metal Sheet cut through Plasma Cutting

|

|

|

|

|

Features:

- IGBT Inverter based technology.

- Full wave output bridge rectifier for smooth cutting arc.

- Digital control with panel meter.

- Stepless current control with current preset facility.

- Contact less Pilot Arcing with built in HF circuit.

- Suitable to cut Mild Steel, Alloy steel, Carbon steel, Stainless steel.

- Cuts Non-Ferrous metals like. Copper, Brass, Aluminum.

- Suitable to cut on Hard faced, Cladded, Rusted, Painted or Expanded surfaces.

- Smooth cut surfaces with minimal Dross and Kerf width.

- Operates on Input supply of 380 - 415 VAC / 3-Phase / 50-60 Hz.

- Air fail safe trip to protect torch and consumables.

- Overheat safe trip to protect internal circuits.

- Extended life of Torch and Consumables.

|

Package:

- Power Source

- Air filter/Regulator

- Starter Kit

- Hand Torch - 7mtrs cable.

- Earthing clamp 7mtrs cable.

- Machine mounting trolley.

Options:

- Torch & Earthing cable up to 30 meters length.

- Water Cooled Torch

- Circle cutting attachment

- 100% duty cycle & CNC interfacing for mechanised cutting

|

|

|

Arcraft is one of the leaders and well established brand in Air / Gas plasma cutting equipments. The plasma cutting machines manufactured are one of the best in quality manufactured to stringent standards, rugged and suitable to work in tough environment. The Air / Gas plasma cutting systems of Arcraft brand are fully indigenous. Arcraft offers one of the widest range of Air and Gas plasma cutting torches and consumables in Air cooled as well as Water cooled versions. Different designs with modern polymer materials make Arcraft torches most reliable and efficient suitable for Air and Gas plasma cutting with plasma mediums like Air, Nitrogen, Argon, Argon+Hydrogen as per the demand and requirements.

Check out our manufactured Plasma Cutting Machines benefits, specifications, applications :

power sources ( Inverter based )

Specification

| Model : ARC CUT |

10i |

16i |

25i |

30i |

40i |

50i |

| Cutting Capacity (SS/MS) |

|

|

|

|

|

|

| Clean Cut (mm) |

6 |

10 |

16 |

25 |

32 |

40 |

| Parting Cut (mm) |

10 |

16 |

25 |

32 |

40 |

50 |

| Torch Cooling |

Air |

Air |

Air |

Air |

Air |

Air |

| Duty Cycle % |

100 |

100 |

100 |

100 |

100 |

100 |

| Input Power |

|

|

|

|

|

|

| 3 Phase / 50 Hz / 4 Wire |

|

|

|

|

|

|

| Input Volt |

380/415 |

380/415 |

380/415 |

380/415 |

380/415 |

380/415 |

| Rated Input KVA |

4.8 |

6.5 |

9.8 |

12.8 |

15.5 |

19.5 |

| Output Current DC (Amp) |

30 |

40 |

60 |

80 |

100 |

120 |

| Max. OCV Volt |

260 |

260 |

260 |

260 |

260 |

260 |

| Plasma Gas |

Air |

Air |

Air |

Air |

Air |

Air |

| Pressure Kg/cm2 (Bar) |

6 |

6 |

8 |

8 |

8 |

8 |

| Flow CFM / LPM |

2.5/70 |

2.5/70 |

3.5/100 |

3.5/100 |

3.5/100 |

3.5/100 |

| Dimension (mm) |

|

|

|

|

|

|

| Width |

255 |

285 |

285 |

340 |

340 |

340 |

| Height |

410 |

510 |

510 |

570 |

570 |

570 |

| Length |

450 |

565 |

565 |

670 |

670 |

670 |

| Weight (Kg) |

19 |

25 |

34 |

45 |

53 |

60 |

| Air Compressor Specs. |

|

|

|

|

|

|

| CFM / LPM |

10/283 |

10/283 |

15/425 |

15/425 |

15/425 |

15/425 |

| Bar |

9 |

9 |

11 |

11 |

11 |

11 |

| Motor Hp |

3 |

3 |

5 |

5 |

5 |

5 |

| Cylinder |

Twin |

Twin |

Twin |

Twin |

Twin |

Twin |

| Model : ARC CUT |

60i |

70i |

80i |

100i |

125i |

150i |

| Cutting Capacity SS/MS |

|

|

|

|

|

|

| Clean Cut (mm) |

50 |

60 |

70 |

80 |

100 |

125 |

| Parting Cut (mm) |

60 |

70 |

80 |

100 |

125 |

150 |

| Torch Cooling |

Water |

Water |

Water |

Water |

Water |

Water |

| Duty Cycle % |

100 |

100 |

100 |

100 |

100 |

100 |

| Input Power |

|

|

|

|

|

|

| 3 Phase / 50 Hz / 4 Wire |

|

|

|

|

|

|

| Input Volt |

380/415 |

380/415 |

380/415 |

380/415 |

380/415 |

380/415 |

| Rated Input KVA |

25.5 |

28.3 |

32.5 |

62 |

93 |

124 |

| Output Current DC (Amp) |

150 |

180 |

200 |

400 |

600 |

800 |

| Max. OCV Volt |

260 |

260 |

260 |

260 |

260 |

260 |

| Plasma Gas |

Air |

Air |

Air |

Nitrogen |

Nitrogen |

Nitrogen |

| Pressure Kg/cm2 (Bar) |

3 |

3 |

3 |

3 |

3 |

3 |

| Flow CFM / LPM |

1/28.3 |

1/28.3 |

1/28.3 |

1/28.3 |

1/28.3 |

1/28.3 |

| Dimension (mm) |

|

|

|

|

|

|

| Width |

395 |

395 |

395 |

790 |

790 |

790 |

| Height |

1240 |

1240 |

1240 |

1240 |

1635 |

2030 |

| Length |

745 |

745 |

745 |

745 |

845 |

945 |

| Weight (Kg) |

91 |

105 |

125 |

280 |

410 |

580 |

| Air Compressor Specs. |

|

|

|

|

|

|

| CFM / LPM |

15/425 |

15/425 |

15/425 |

-- |

-- |

-- |

| Bar |

11 |

11 |

11 |

-- |

-- |

-- |

| Motor Hp |

5 |

5 |

5 |

-- |

-- |

-- |

| Cylinder |

Twin |

Twin |

Twin |

-- |

-- |

-- |

Descriptions

PlasmaCutting Machine consists of a Power source with suitable controls, Water Re-circulating system when required and a well designed Torch. The basic principle is that the arc formed between the electrode and the work piece is constricted by a fine bore copper nozzle. This increases the temperature and velocity of the plasma emitting from the nozzle. The temperature of the plasma is in excess of 20,000°C and the velocity can approach the speed of sound. When used for cutting, the plasma gas flow is increased so that the deeply penetrating plasma jet cuts through the material and molten material is removed in the efflux plasma.

Applications:

It can cut all electrically conductive metals like S.S, C.S, Copper, Aluminum, Inconel, Titanium, etc. Metals like Stainless Steel & Aluminum cannot be cut by Oxy - Acetylene as the metal reacts with oxygen during cutting to form oxides whose melting point is higher than the temperature of the Oxy-Acetylene flame. Plasma Arc temperature are in excess of 20,000oC with the high velocity flow which blast through all metals with a very clean finish at high speed.

- Cut expanded metal, painted or rusted plates

- Nonlinear cuts and beveling for edge preparation before welding

- Gouging can be performed just by changing the nozzle

- Hand held and mechanized options available

Water Chiller

|

- Water chiller cum re-circulator available for Plasma cutting machine ARC CUT 60i and above.

- It maximizes torch productivity by efficiently cooling the torch therby increasing the working life of the consumables..

- Installed with imported compressor, efficient condensers and evaporators.

- Excellent cooling and low electricity consumptions

Specifications:

| Capacity |

1 Ton |

2 Ton |

3 Ton |

5 Ton |

| Flow Rate |

5 lpm |

5 lpm |

5 lpm |

5 lpm |

| Outlet Temperature |

10 – 25 °C

Adjustable |

10 – 25 °C

Adjustable |

10 – 25 °C

Adjustable |

10 – 25 °C

Adjustable |

| Input |

415 VAC / 3-Ø / 0.5 Hp |

415 VAC / 3-Ø / 0.5 Hp |

415 VAC / 3-Ø / 0.5 Hp |

415 VAC / 3-Ø / 0.5 Hp |

| Tank |

25 ltrs |

60 ltrs |

200 ltrs |

300 ltrs |

|

Automation

- Automation available with trolley with rail and profile cutting systems.

- One can adjust the speed of machine according to the thickness of the cutting plate with speed controller nob.

- This machine can cut the plates in straight direction and also cut in round shape with the help of circle cutting attachment.

- Advanced automation available with CNC cutting systems.

Torch Cable

- Outstanding toughness and durability.

- High resistant to cut, wear and abrasion.

- Resistant to oil, solvents and chemicals.

- Available in standard size of 7 meter (available even upto 30 meters).

Earthing clamp

- High conductivity, bare annealed copper flexible conductor.

- The cable is extremely resistant to light, chemical and mechanical damage and it maintains its flexibility.

- Earthing clamp with 7 meter cable.

Torch

- Available in air and water cooled type.

- Hand held and mechanized.

- Available in different range to cut from 10mm to 150mm thick plates

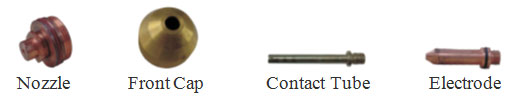

Consumables

- Our consumables for plasma cutting system ensure optimal performance.

- Our torches and consumables have the latest performance enhancing technologies and are machined to the highest quality standards.

We manufacture Plasma Cutting Machines - Automation available with portable trolleys with Rail, Profile cutting systems and CNC cutting systems. Quotation on request

Features and other details on Air/Gas Plasma Cutting Machines

Technical Data - Getting the best of your plasma cutting consumables

CNC GAS / PLASMA PROFILE CUTTING SYSTEMS

|